Warehouse Layout and Process Design

Layout design work supported with AutoCAD drawings as required

Data analysis to identify fast / slow moving stock items – detailed analysis to determine optimum strategy for each product group

Review of current and potential storage medias to meet desired throughputs and storage needs

Design of value add, processing and marshalling spaces in line with projected demand

Comparison of storage media types - alternate layout designs and calculation of storage capacities and impact on throughput for each alternative.

Cost modelling analysis of alternative concepts.

Operational Resource Planning

Detailed analysis of operational volumes through various stages

Creation of MOST models or time studies to calculate task rates (KPI’s)

Resource modelling – to model effect of receipts / picking operations through the year/ week / day / hour – this tool then calculates resources required to meet forecasted demands

Cost modelling

The resource tool is used to calculate labour / MHE resource requirements over a period of time, taking into account seasonal volume fluctuations. From the tool various charts and graphs can be produced. Once set up the impact of say reducing the number of trucks in the warehouse can quickly be calculated. Also, if additional resource is required (e.g. short-term hire equipment, or agency staff), these can be added to the impact on the operation can be reported.

Logistics Network Design

Modelling of Network

Modelling impact of change with the number of sites and location and size of sites

Centre of Gravity analysis

Financial comparison of alternative strategies

Identification of optimum network design

Warehouse Automation Design / Evaluation

Performing modelling and analysis of volumes through current operation

Evaluation of automation equipment and recommendation of options

Review of impact on throughput rates and resources required with automation

Modelling of forecast growth and order volumes and impact on operations

Cost Payback Analysis on Capex projects

Warehouse Management Systems

Review of current WMS (Warehouse Management System) - functionality review / fit for purpose analysis

Process Mapping of Operations and if required mapping to a WMS

Specification of WMS for potential vendor quotation

Documentation of training materials and supporting training during go live

Integration to WCS (Warehouse Control Systems)

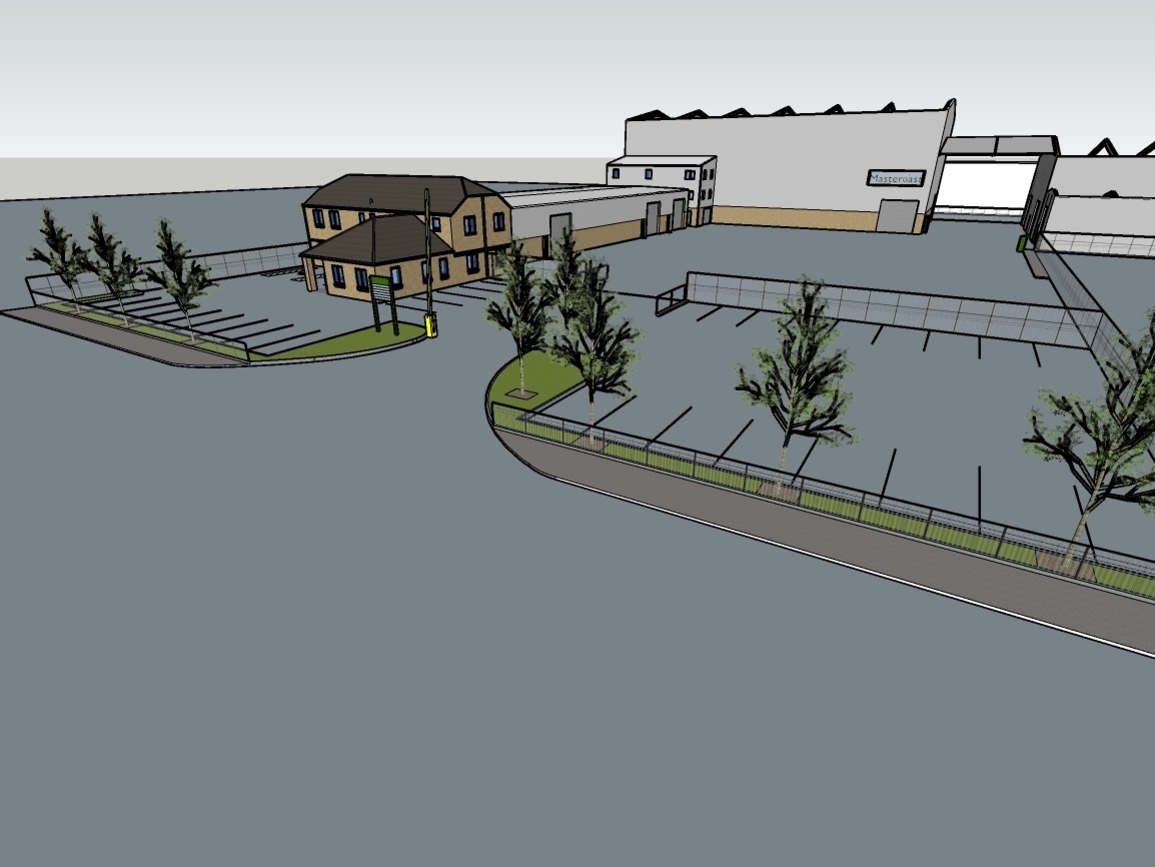

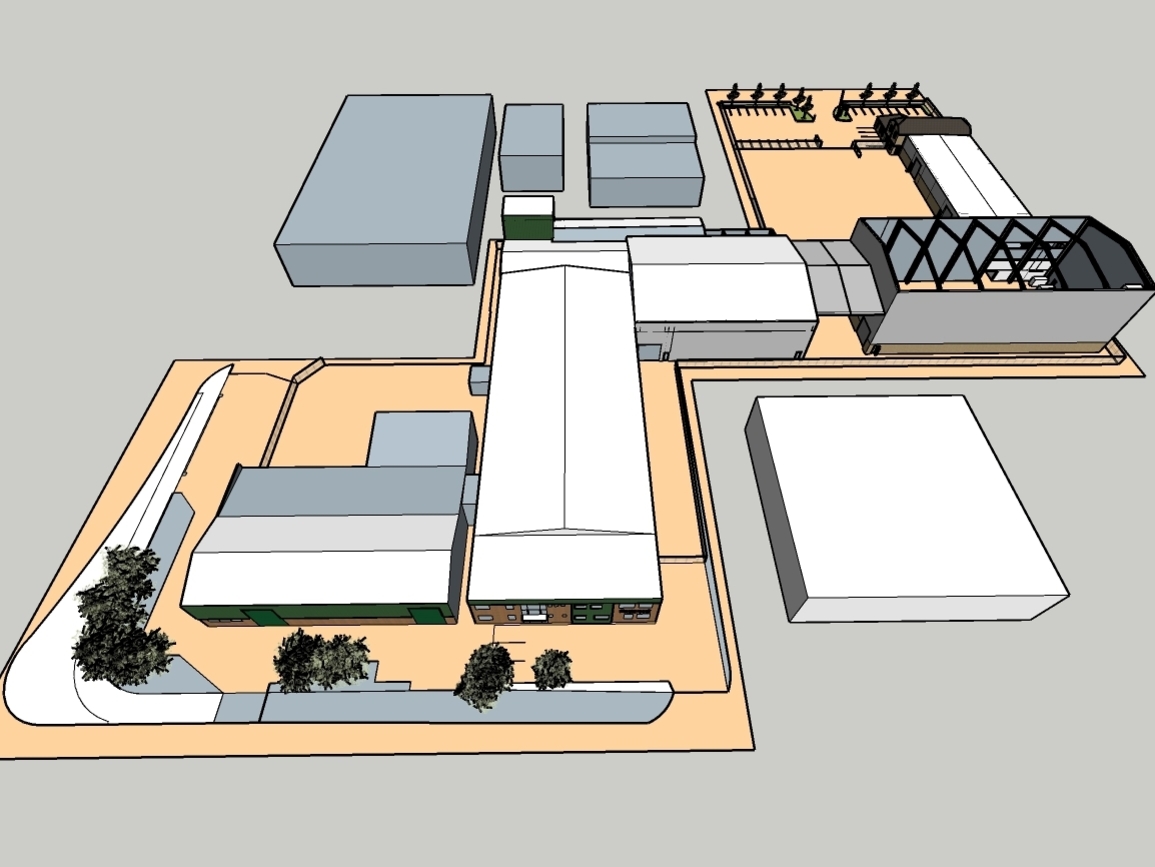

New Build Warehouse Design

This is an outsourced service supplied through one of my trusted partners as part of my project.

For help and advice on any of these services call Tony on 07960 213193

or email tony@thlogisticsconsultant.com