Warehouse Design – Simulation and Emulation (Part 2 of 2)

Posted on 10th August 2022

In my series of Blogs, we have looked at how a warehouse design can be tested and validated by means of modelling, and simulation using the K. Sight CLASS Simulation software. This Blog is the 2nd and final instalment of the simulation Blog’s and will focus on Demo 3D. Demo 3D is used by most of the leading warehouse automation suppliers and integrators, and therefore this Blog will focus on how this software might be applied.

Demo 3D – Dematic

This Blog will look at the role that layout and modelling, then simulation and ultimately emulation could take as part of the evaluation and design, review and testing process for an automated application using Demo 3D.

During the research for this Blog Logistex has supported the process and contributed with images and screenshots, so a big shout out to the team there!

Overview

As previously stated, more and more companies are now reviewing in detail their warehouse operations, and increasingly we are seeing increasing take up of automated options. These options will need to be assessed, compared to alternatives, validated and simulated.

This Blog will focus on the most popular software used by Automation suppliers and Integrators - Demo 3D. In 2019 Rockwell Automation acquired Emulate 3D the company that developed the suite of software, there are numerous applications of the software, in this blog we will focus on 4 that are popular in warehouse design automation:

Layout 3D – used to generate layouts

Demo 3D – used to demonstrate equipment in operation in the layout

Sim 3D – used to simulate operations

Emulate 3D – used to test control systems.

The sequence above is a logical sequence that would be adopted with each stage being completed before moving onto the next stage. Layouts and models created in Layout3D can be opened and modified by Demo3D, Sim3D, and Emulate3D.

As you can imagine, as the product capabilities and functionality increase, so does the licence cost of the software. The time to learn and master the functions and ultimately the required specialist skills of the user also increases.

Why use Demo 3D – Layout, Demo, Simulation and Emulation?

There is a wealth of automation equipment types to choose from, in my previous Blog we discussed 9 different types of sorter for example, as well as different operating strategies, each offering various advantages and constraints. Add to this the experience and opinions of everyone involved in the design process, including the end users and the result can be compared to the “A camel is a horse designed by a committee” analogy.

To understand the reason you might apply simulation techniques is discussed in more details in the first Blog about simulation, so this will only be discussed briefly.

Automation suppliers may during initial sales discussions demonstrate a concept using Demo 3D or Sim 3D – to help customers conceptualise a solution, this helps considerably in the sales process, especially if competing against others who may only demonstrate their solutions with AutoCAD drawings and spreadsheet analysis.

Ultimately Emulate 3D is used as proof of concept – giving confidence that a solution is mechanically sound by means of performing acceptance testing of controls in advance of building the system on site.

User Training

www.demo3d.com/workshop/

Users can register for an online training course / workshop. The course comes with a full product licence for 3 weeks and has 5 x 1-hour workshop for 5 days supported with videos. This will provide users with the basic knowledge to complete basic layouts and demos.

Advanced users with knowledge of advanced warehouse automation and systems will possibly be able to self-learn some of the techniques required to complete simulations to the Sim 3D level.

However, emulation and the application of Emulate 3D will require a higher level of training supplied by experts in the particular field of application (whether this be warehouse automation, baggage handling systems, or automated machinery used in production facilities). Also, the user will need to have vast experience of automated systems and controls, an advanced knowledge of PLC’s and controls systems logic and integration. This work is either completed in house by Automation suppliers or subcontracted out to specialist contractors.

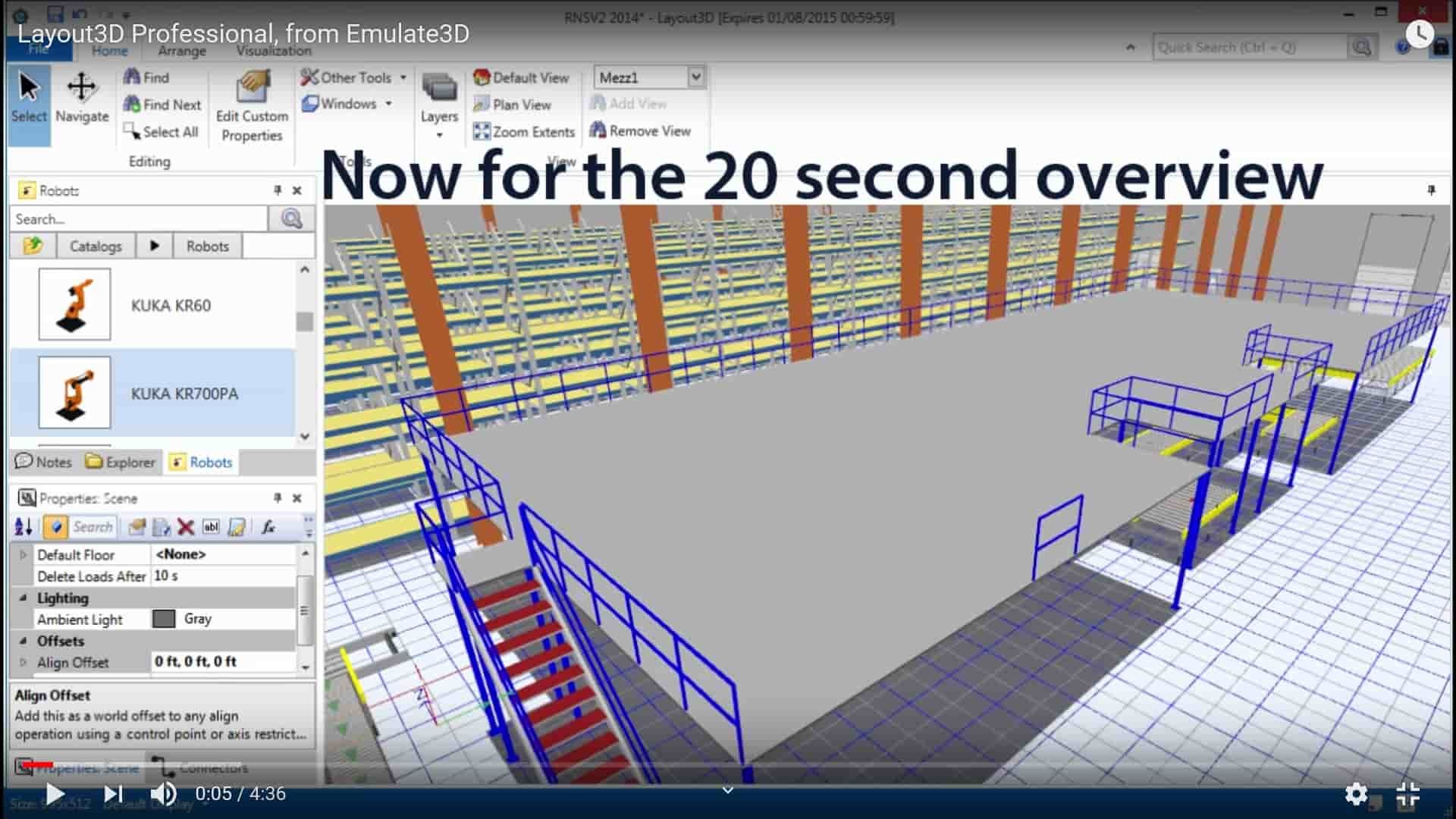

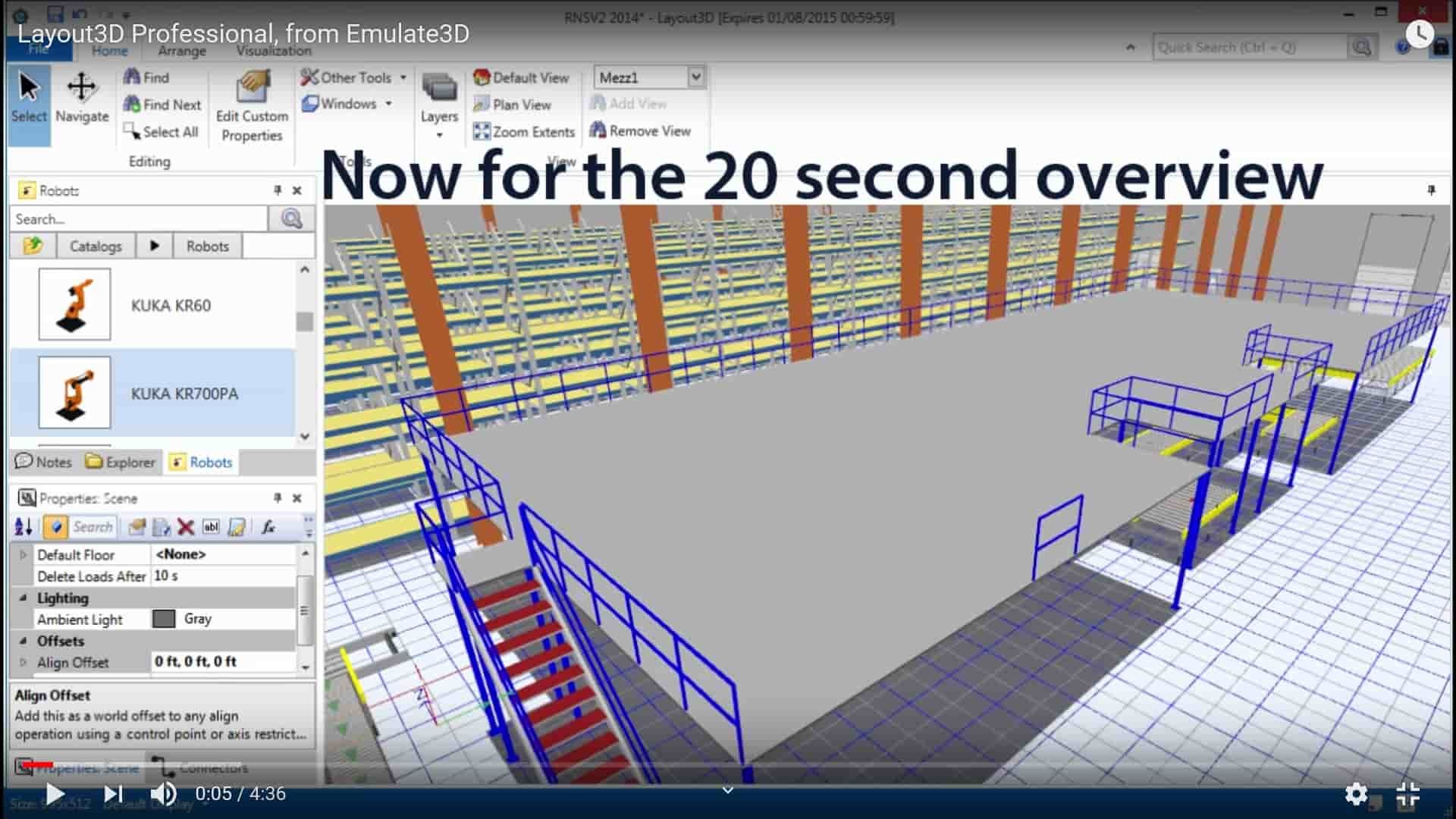

1. Layout 3D

Layout 3D is used to create accurate and realistic looking 3D layouts of a wide range of storage media and automation equipment in warehouse and distribution centres. Layout 3D models can be quickly generated and used to demonstrate, explain and develop project solutions.

Virtual tours of a new facility or planned changes to an existing facility can be viewed using a standard games controller. In addition videos and renders can be generated.

Starting the layout Process

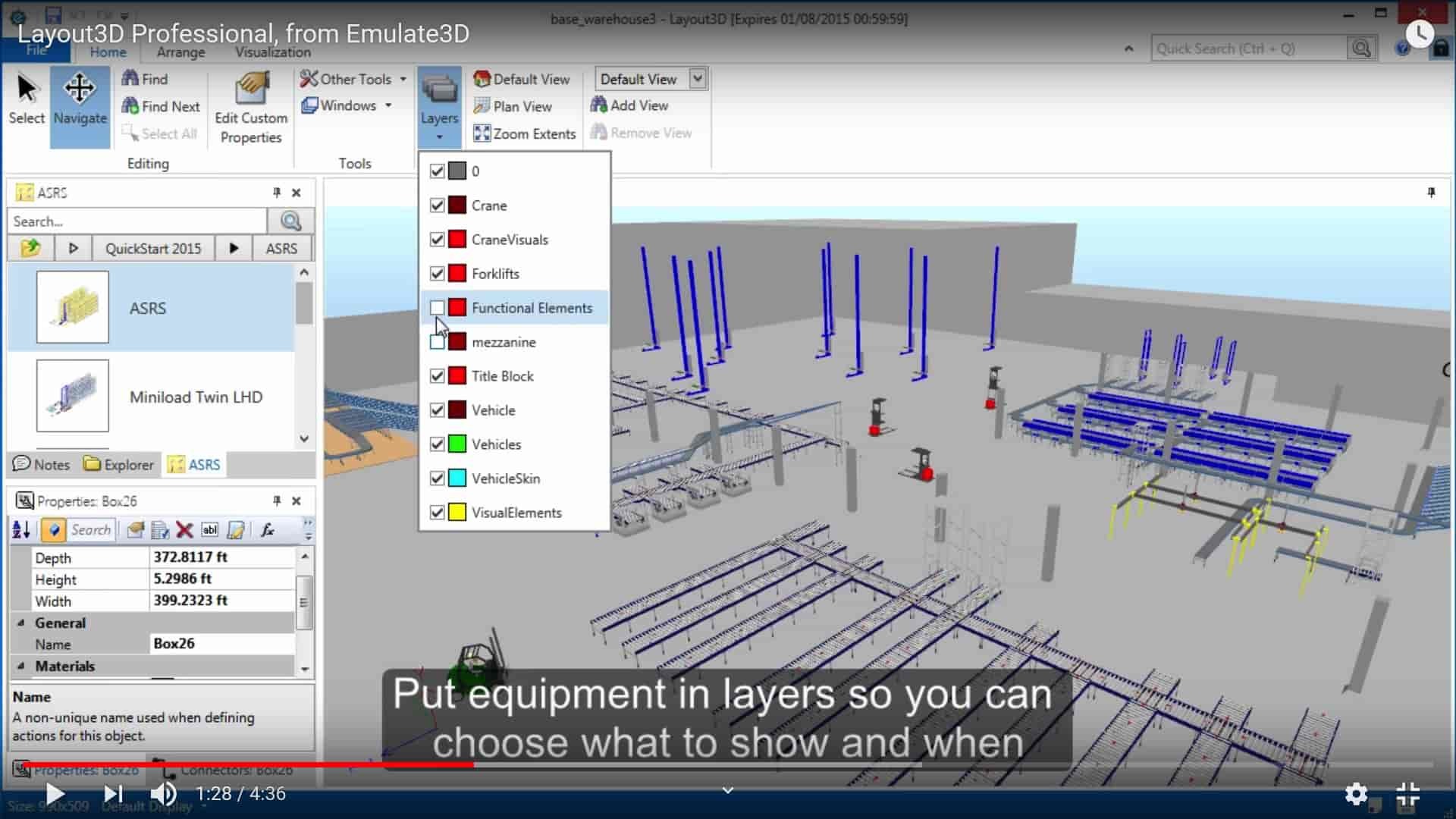

For ease of drawing the objects can be located on separate layers – layers can be switched on / off at the user’s discretion for demonstration, 3D rendered images / video capturing. Ideally you would create the warehouse layout first, showing the extents of the warehouse. Layouts can also be imported to scale in AutoCAD .dwg format and overlayed with design objects.

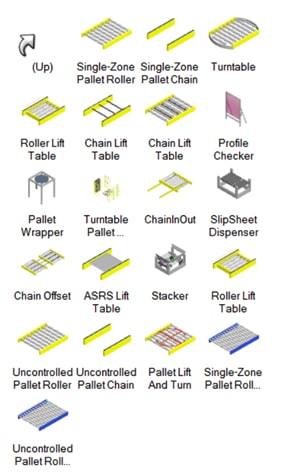

Layouts can be generated quickly using the quick Start suite of pre-installed catalogue of objects, material handling equipment including conveyors, warehouse trucks, ASRS systems, are included in the catalogue. These objects are simply dragged onto the screen, aligned and connected to each other. They can be resized by entering new dimensions or stretched using grab handles. Objects such as racks and gantry cranes can be imported, and these can be easily re-sized and extended as required. 3D CAD drawings of equipment you can import from CAD formats. You can create your own library of company-specific catalogues. Objects can also be imported from SolidWorks, Inventor, Solid Edge and Sketch Up amongst others.

When a layout is complete it can be exported in AutoCAD .dwg format.

Sample Catalogue elements - QuickStart catalogue

Point Cloud imports - A point cloud is a set of data points in space. The points represent a 3D shape or object. Each point has its set of X, Y and Z coordinates. Point clouds are generally produced by 3D scanners or by photogrammetry software, which measure many points on the external surfaces of objects around them.

Videos & Presentation

Outputs can include animated 3D PDF documents and videos. Videos can be created using a fly through process, the software will generate an automatic camera path which can be modified quickly by the user using grab handles.

The user can also set views and the camera will travel between the views with varying speeds and delays. Advanced user could also set a camera on a load, and create a Go Pro style action video, moving through a warehouse through various points.

Layout 3D – Virtual Reality Visualisation

You can also view warehouses using Virtual reality glasses / 3D equipped laptops and controllers such as X Box. The HTC Vive and Samsung Gear VR are popular ways to view a warehouse using VR technology.

2. Demo 3D

Demo 3D – Robot Picking Operation

Demo 3D – Autonomous Mobile Robots

3. Sim 3D

Demo 3D Sorter / Belt Emulation

The overall flow through a system can be modelled and adjusted to meet your requirements. Dimensions of racks, conveyors, and storage areas can be compared and simulated to determine the impact of any change.

Equipment speeds and cycle times can be set. Downtime for maintenance and breakdowns can be factored into the simulation. A skilled user of the simulation software will know how complex and detailed the simulation should be to meet specific project requirements.

Sim3D is used to analyse the system throughputs, identify bottlenecks, dimension layouts accurately, and to make “What if” changes and measure the outputs. You can add rate counters to the outputs and view the results whilst simulating the operation. This topic is also covered in the next section - Emulate 3D.

4. Emulate 3D

Emulate 3D – with event counter

Commissioning of Automated Systems

The commissioning process (often referred to as “acceptance testing”) includes achieving, verifying, testing, accepting, and documenting that the performance of mechanical systems meets design intent and the owner needs.

The traditional approach to commissioning of any automation system is a challenging and often stressful process for all involved. The hardware and the controls interact for the first time, products are introduced into the system, and operators are trained on how to operate it. Despite the possible use of many standard automation components in an automated system, each one will be considered as a prototype and will require testing. Controls testing is always on the critical path on any project plan. Delivering a project late could result in penalties for the supplier, and the damaging effect of a poor system installation cannot be overstressed, and what should be a long-term harmonious relationship between supplier and customer can easily be sourced from the offset.

Emulate 3D allows for Offline Controls Testing

Emulate3D Virtual Controls Testing allows comprehensive testing using an accurate Digital Replica of the real system, earlier in the project cycle (taken off the critical path), and at a lower cost, than is possible using traditional techniques. Any problems identified during the testing phase can be addressed and rectified before going to the site.

Emulate 3D Summary:

Emulate 3D can simulate warehouse controls software and drive the relevant PLC’s

Emulate used to test before going live

Interface the WCS to the PLC’s – controls logics and protocols – exact replication of the software will reduce testing before going live, issues can be identified early in the process

Use real historical order data set to drive the emulation

Manual operations can be used to incorporate delays to the automation, such as a manual picking operation in a work zone – the duration of these delays can be calculated using time study rates, or rates generated using MOST or MTM techniques.

Controls logic can be created in Emulate 3D using C#, Microsoft JScript, QuickLogic, Ladder Logic, or Sequential Function Charts.

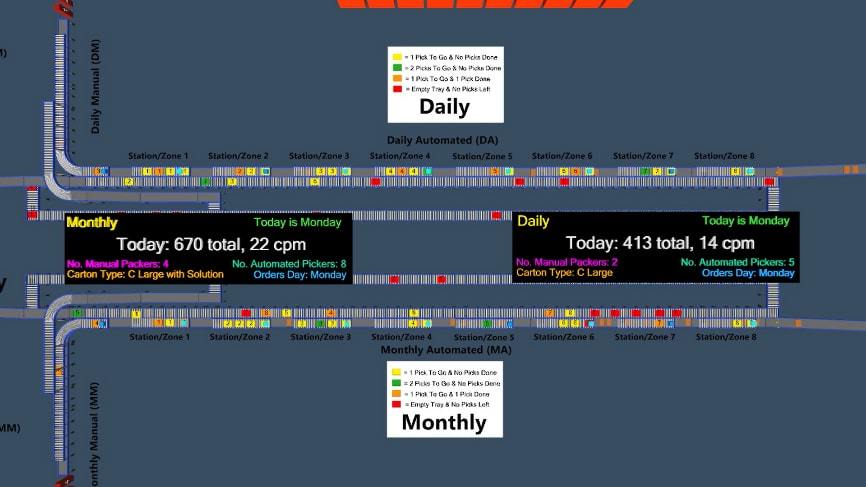

Emulate3D Controls Testing - Emulation modelling – outputs

The Emulate software replicates a given period of operation and when running can show the following:

Event tracker

- Idle time

- Picking time

- Waiting to return items to conveyor due to congestio

- Pushing onto the conveyor.

Utilisation reports – e.g. if warehouse operators are manning a workstation you report how occupied they are

The emulation can be “re-run” with changed parameters – for example you could change some logic around the number of cartons held at a buffer point, the emulation can be re-run and you can monitor the results on the screen during the running of the emulation, and make adjustments as required.

few systems remain unchanged during their lifecycle, so any proposed modifications should again be evaluated offline first, using Emulate 3D, prior to implementation.

The final outputs of the emulation include:

Sets of various configurable reports which can be extracted and analysed in a spreadsheet format

Video capture – with counters displaying key process information – i.e. various colours can be assigned to totes / trays / pallets / parcels in the emulation and the colours can change to signify status of the item, i.e. part picked, picked / empty / return to stock.

Sample Emulation with event counter

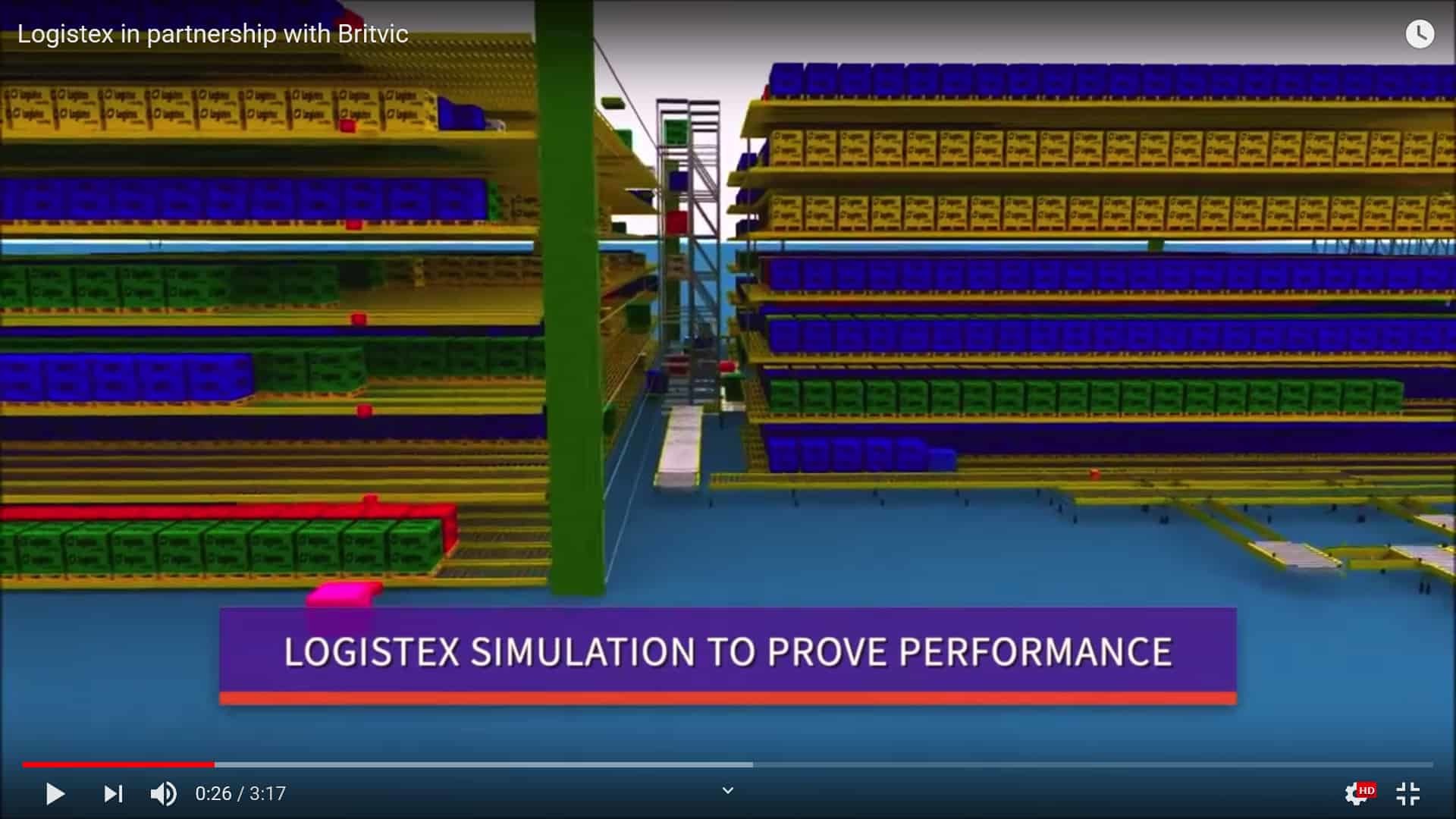

As previously mentioned, I have been helped with some of the advanced technical aspects relating to Demo 3D by my contacts at Logistex. You can see how Logistex in house designers used Emulate 3D on one of their recent projects here.

Emulate 3D – extract from Logistex YouTube video

As previously stated, the Emulate software licence is more expensive than the other Demo 3D licences. Specialist knowledge of software coding is required, plus high-level knowledge of controls software logic. The Emulate 3D process will be at a high costs level compared to the previous stages however, this step should not be omitted from any project and is vital to a successful implementation. Any costs associated with Emulate 3D will be offset by savings achieved as a result of reducing the commissioning time.

Conclusion

Any investment in automation, new layouts or new equipment should be based on a sound understanding of the current operation and future growth projections. The design process and the evaluation and simulation of the operation coupled with the ability to ultimately emulate the control logic in advance of go live is invaluable.

Before committing to any major investment in automation the assessment of alternative concepts should be assessed by impartial, independent experts.

If I can help you with modelling or simulation, or any other aspect of warehouse operations design, please do not hesitate to ask for any advice. I would of course be delighted to provide a quotation to provide any assistance required.

Share this post: