Warehouse Design – Efficient Operations and KPI Reporting

Posted on 26th July 2022

In my series of Blogs, we have looked at various aspects of warehouse Design. The subjects covered so far include different types of warehouse automation including “Goods to Man” picking solutions supported by Robots and Cobots, Sorters, Shuttle Racks and various storage equipment options. For each alternative handling and storage solution, the main objective for the designer is to provide a cost-effective efficient solution to meet the requirements of the business, and ultimately the end customer.

In this Blog, we will in the first instance discover what is the difference between efficiency and productivity.

We will then review some of the most common warehouse Key Performance Indicators (KPIs) and the reporting outputs that are commonly used and how they are applied, and the value that setting and measuring KPIs brings.

In my next Blog we will then discuss how an Industrial Engineer or Lean Practitioner, would set KPIs using work measurement techniques including Time and Motion studies, and synthetic tools such as Most or MTM.

This is a detailed and complex area of analysis, but please persevere, I am sure you will learn something from this fascinating subject. I would suggest that with the increasing popularity of the latest automation solutions being adopted in warehouses, the process of understanding the current operational efficiencies and associated productivities is a key component in the decision-making process.

Overview

A repetitive statement in my previous Blogs is that more and more companies are now more than ever scrutinising their warehouse efficiency. Labour costs are continuing to increase, and the availability of labour has reduced. Companies are now competing with other companies to attract and retain staff by offering competitive wages and favourable working conditions. The Covid 19 pandemic has also resulted in many cases a redesign of the workplace, with operational changes implemented in order to comply with safer working practices.

We have seen significant increase in online sales that has resulted in considerable changes to warehouse operations. We are seeing more warehouses acting as fulfilment centres, as opposed to distribution centres.

It is now more important than ever before for companies to be successful they must be designed to allow for efficient operations. It is also imperative that we have productivity targets (KPIs), and that we measure our performance against these targets. With this information we can establish if there is a trend of improvement or if performance is deteriorating, and in each instance investigate the root cause.

Having accurate KPIs also allows us to plan more accurately for peaks in demand, and also allows us to benchmark the operation against other similar operations or competitors. We can also use the information for financial analysis and for estimating costs of new operations.

What is the difference between productivity and efficiency?

Put simply, productivity is the quantity of work produced by a team, business or individual. Efficiency, on the other hand, refers to the resources used to produce that work. So, the more effort, time or raw materials required to do the work, the less efficient the process.

Productivity deals in the rate at which results are achieved, but efficiency focuses instead on the resources invested and the level of waste involved.

Operators that work harder will have a higher productivity rate, and this is obviously more favourable than operators that need to be chased, encouraged (possibly with a financial incentive – such as a productivity-based bonus scheme), or cajoled into working hard. The following factors might be a contributing factor for higher or lower levels of productivity:

areas/regions of high unemployment

the age of staff

physical fitness of staff.

TH Comment: for further research into workforce motivation, I would suggest a google search on “McGregor's Theory X and Theory Y”, and “Maslow's Hierarchy of Needs”.

TH Comment – as a consultant, all too often I visit a customer site for the first time and notice some or all of the following inefficiencies:

Poor layout design – leading to excessive travel distances

Excessive movements – movements that add no value – especially trucks travelling with empty forks, and dual cycling opportunities missed due to poor work scheduling

Poor slotting – badly applied allocation of ABC stock profiling, possibly the result of not having a housekeeping programme to reposition SKU’s based on velocity

Excessive replenishment distances due to high overall stock levels in the warehouse

Inefficient picking due to waiting on replenishment of pick faces, and poorly managed replenishment processes

Not using the Warehouse Management System (WMS) correctly – operators using short cuts, choosing to bypass the system, this is typically more problematic in the case of put away, picking and replenishment

Bottlenecks – e.g., a good example could be returns not processed in a timely manner, delays on inbound receipt checking, excessive consolidation at despatch.

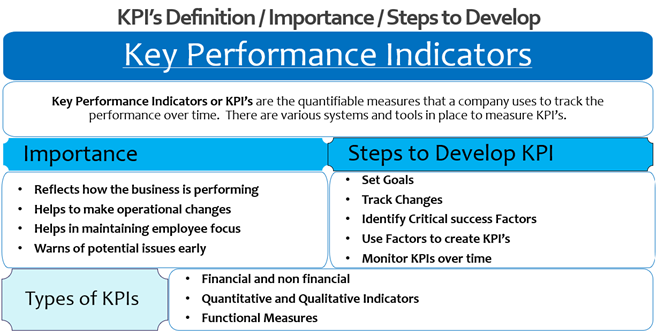

What are KPIs?

In my Blog : Data Analysis I stated that when I engage with a client on a warehouse design project, at the start of the project I issue a data request proforma. Within this request it will include a list of KPIs, and I also ask for the current performance against the KPIs.

TH comment: a well-run site will provide a detailed list of both the current KPIs and the actual rates. This does not necessarily mean it is an efficient and productive site.

Example Warehouse KPIs used within warehouse operations

Operational

Item / Line / Case / Pallet pick rate – typically expressed in units per hour worked

Orders picked per shift / day / week / month

Outbound loads per hour

Inbound receipts per hour – processing time to put away

Pick accuracy – at SKU level, unit level or financial level.

% of orders picked on time

Order Fill Rate

On-time delivery (OTD).

TH Comment – as picking typically accounts for at least 60% of the overall labour hours, a KPI which relates to picking performance is generally the most valuable Operational KPI.

Inventory Related:

Stock availability

Receipts processing - typically a time period to process a receipt from a given arrival time.

Inventory Stock turns

Stock losses – due to damage, theft / obsolescence

Product damage.

There may be other measured site related KPIs such as:

Lost time through sickness

Accidents – lost time / reported

Absenteeism rates.

Note: this is a summarised example, numerous other KPIs might be measured by a company.

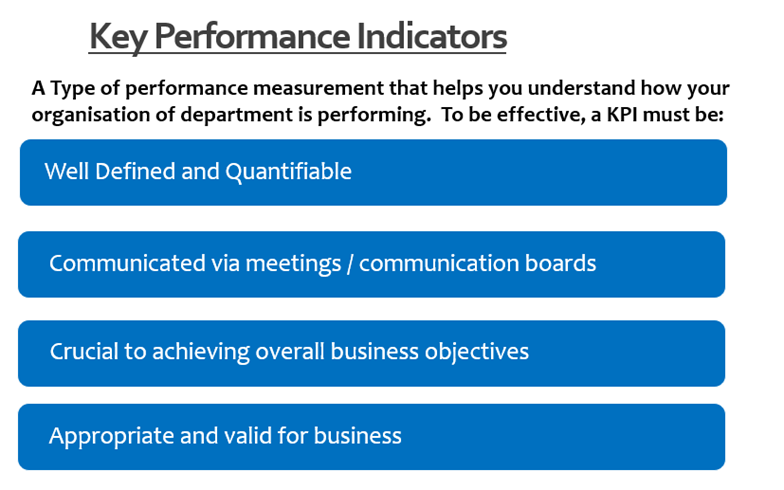

KPI Guidelines

KPIs Guidelines

When setting KPIs you should follow these guidelines:

Quantifiable and measurable – the KPIs should be easy to calculate, maybe extracted from reports generated by the WMS, or through extracted data analysed with spreadsheets.

Critical to the success of an organisation – a company may have a “Mission Statement” and as part of the statement identified “Critical Success Factors” which will include targets, these will be measured through KPI analysis and supported by a programme of continued business improvement.

Business goals – a company should have a clear vision of where they are looking to make ongoing improvements to their operations and focus attention and resource in achieving these objectives. Directed exclusively towards achieving the company’s goals and the customer’s expectations.

Limited number of metrics – The fewer the number the easier it is to calculate the results, and also easier to communicate in a timely manner. It is suggested to limit the main reported KPIs to 5 or 6 measures.

Applied consistently through the company – many distribution companies have regional distribution centres, and it is vital to be able to compare KPIs between different locations. It is not uncommon to compare sites, and to review what a poor performing location might differ to a well performing site.

KPIs should be appropriate and relevant to the business needs and goals. They should provide the key information used for reporting the previous days or weeks activities, and the main focus for driving future performance gains. Your employees should know why you are measuring what you are measuring - and why it is important.

KPIs should also include a quality measure, if staff are incentivised to maximise output, this must not be at the expense of quality.

It is good practice to review your performance measures and KPIs regularly - and check they are having the desired effect - in both the short and longer-term.

How to Use KPI Data

Once a full set of KPIs are available, and appropriate reporting mechanisms are in place a company can use these to monitor performance ongoing. The KPIs should be reported in a timely manner, management should know what their main KPIs are, and why factors may result in higher or lower levels of performance. An operations director should be able to contact the site manager and during a 2-minute conversation armed with 2 or 3 of the key KPIs know whether everything is performing ok.

An example of a Communication Board

The KPIs could form part of a management update, daily, weekly, or monthly reporting. Also, the KPI results could form part of the daily communication briefings with employees, it is not uncommon to generate rivalry between shifts using a KPI metric as a comparison, e.g., comparing pick rates between different shifts. Targets can be set and improving the key KPIs could form part of an improvement programme.

Once a set of KPIs has been established and measuring is performed we can benchmark operations between sites, or to benchmark against competitors. We can also use the information to allow for comparison of alternative concepts, such as the introduction of automation. We can also use the data to aid with pricing. We can also monitor trends, identify if performance is deteriorating, or if improving, and more importantly to understand the reasons, for example, in the case of pick performance there might have been a change in the order profile, (the number of lines picked or the number of units per line).

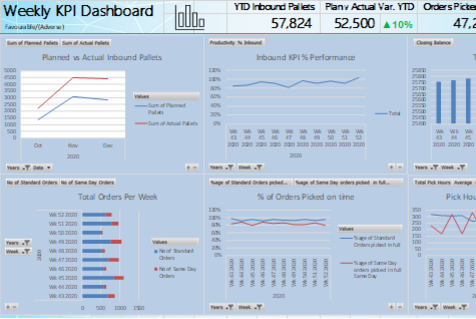

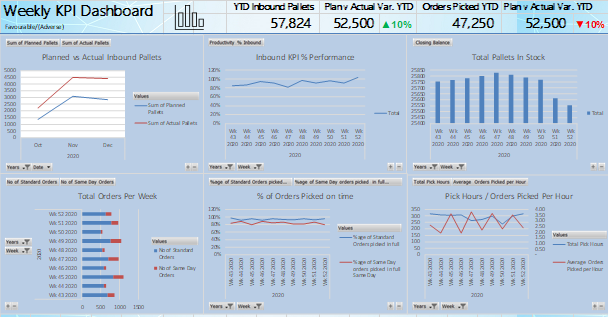

KPIs are often reported using spreadsheets to generate a KPI Dashboard, this is usually a quick to generate report showing key metrics and reporting the most important key information, again limited to 4 or 5 key metrics.

Example KPI Dashboard

Balanced Score Card

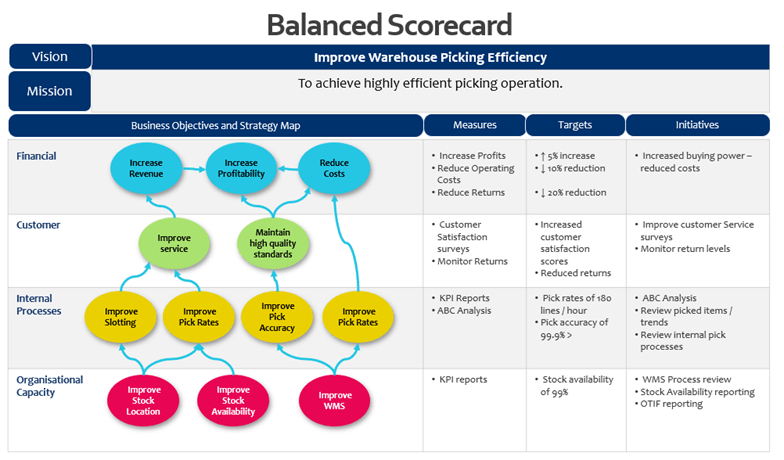

Example Balanced Scorecard

KPIs and associated reported outputs can also be used in reports such as a balanced scorecard. A company that has developed a “Mission Statement” and identified their “Critical Success Factors” will also most likely develop a Balanced Scorecard. Within the balanced scorecard, the overall business objectives and forward strategy is documented, and within the analysis the generated KPIs are used as a vital component of measuring the performance of the operation and reviewed as part of the overall business objectives.

The critical characteristics that define a Balanced Scorecard are:

its focus on the strategic agenda of the business

a focused set of measurements to monitor performance against objectives

a mix of financial and non-financial data items (originally divided into four "perspectives" - Financial, Customer, Internal Process, and Learning & Growth)

a portfolio of initiatives designed to impact performance of the measures/objectives.

3rd Party Logistics Providers and KPIs

In the case of 3rd party logistics providers they generally operate with their customers using two main types of contracts - Open Book or Closed Book, and some contracts are awarded using a Hybrid of the two, with part of the contract fixed price, and some parts variable.

In a closed book contract the 3PL service provider is not obliged to share the operating costs, overheads and margin with their customers. Fees are agreed in the contract based upon a charging mechanism. Contracts are typically 3 or 5 years in duration, and any adjustments in rates are subject to negotiation between the parties at pre-defined intervals. It is not uncommon for a service provider to operate a contract at a loss if they have not estimated the work content of a contract correctly. They will of course look to re-negotiate rates at a later date, which does not foster good long-term relationships with a client. There may be several reasons why a service provider has not set the rates correctly, one of the most common reasons is not having accurate KPIs.

Closed book contracts may also have a form of performance improvement built into the rates, for example the contract might assume a 3% reduction in rates year on year.

In an open-book contract, the customer and service provider will agree on which costs are chargeable and the operating margin that the supplier can add to these costs. The services are invoiced to the customer based on the actual costs incurred, plus the agreed margin.

Conclusion

All businesses are looking to improve their operating efficiencies, coupled with this they should have a real understanding of what their current performance levels are against measurable and appropriate KPIs. When this is in place, it is a great start position if the company is looking to make changes to the current operation, especially if the changes require significant levels of investment.

My next Blog will describe the process of generating KPIs using Industrial Engineering and Lean processes.

If you are setting up KPIs, or considering making changes to your layout, redesigning your operating methods, or considering investing in automation, the assessment of alternative concepts should be assessed by impartial, independent experts. If I can help you with setting KPIs or creating appropriate reporting mechanisms, or any other aspect of warehouse operations design, please do not hesitate to ask for any advice. I would of course be delighted to provide a quotation to provide any assistance required.

Share this post: